Sometimes what you won't do seems to be as important as what you intend to do.

I want to be seen as original. I'm not cut from the same cloth anyway. After the trial period, I want to publish subsequent installments behind a paywall. This is how I plan to cover my expenses to maintain this site.

For now, I'm conducting research, comparing online courses and tutorials to see what I can bring to the table. At the same time, I already have an interesting idea for showcasing my favorite shoemaking tools from Starko, offering you tips and useful information, showing how I use them in my daily work. I'll be starting this series soon.

Time will tell what this little side project will become. I want something fun, yet useful. Playful, yet intelligent. Cool, but in a new, original way.

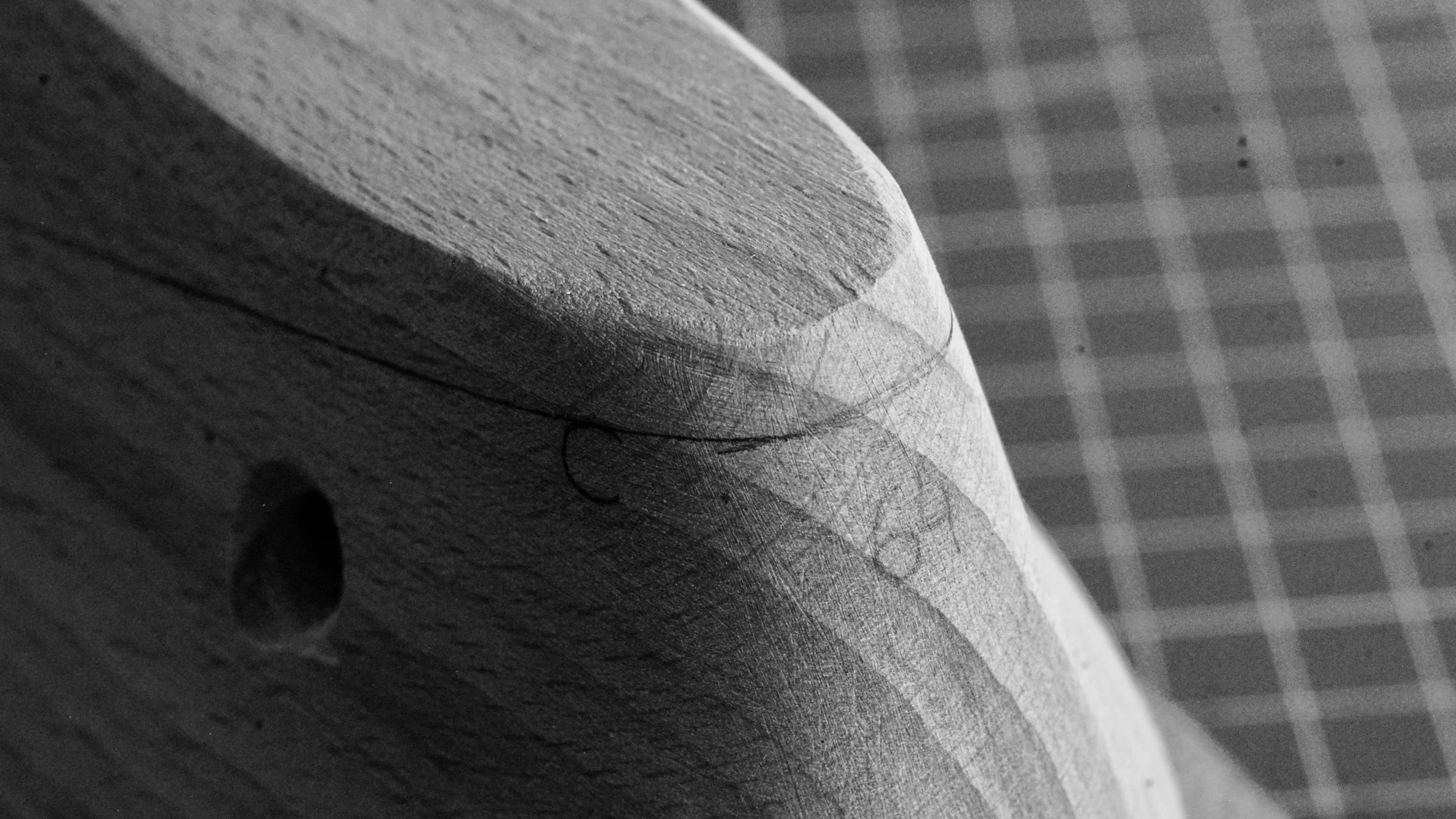

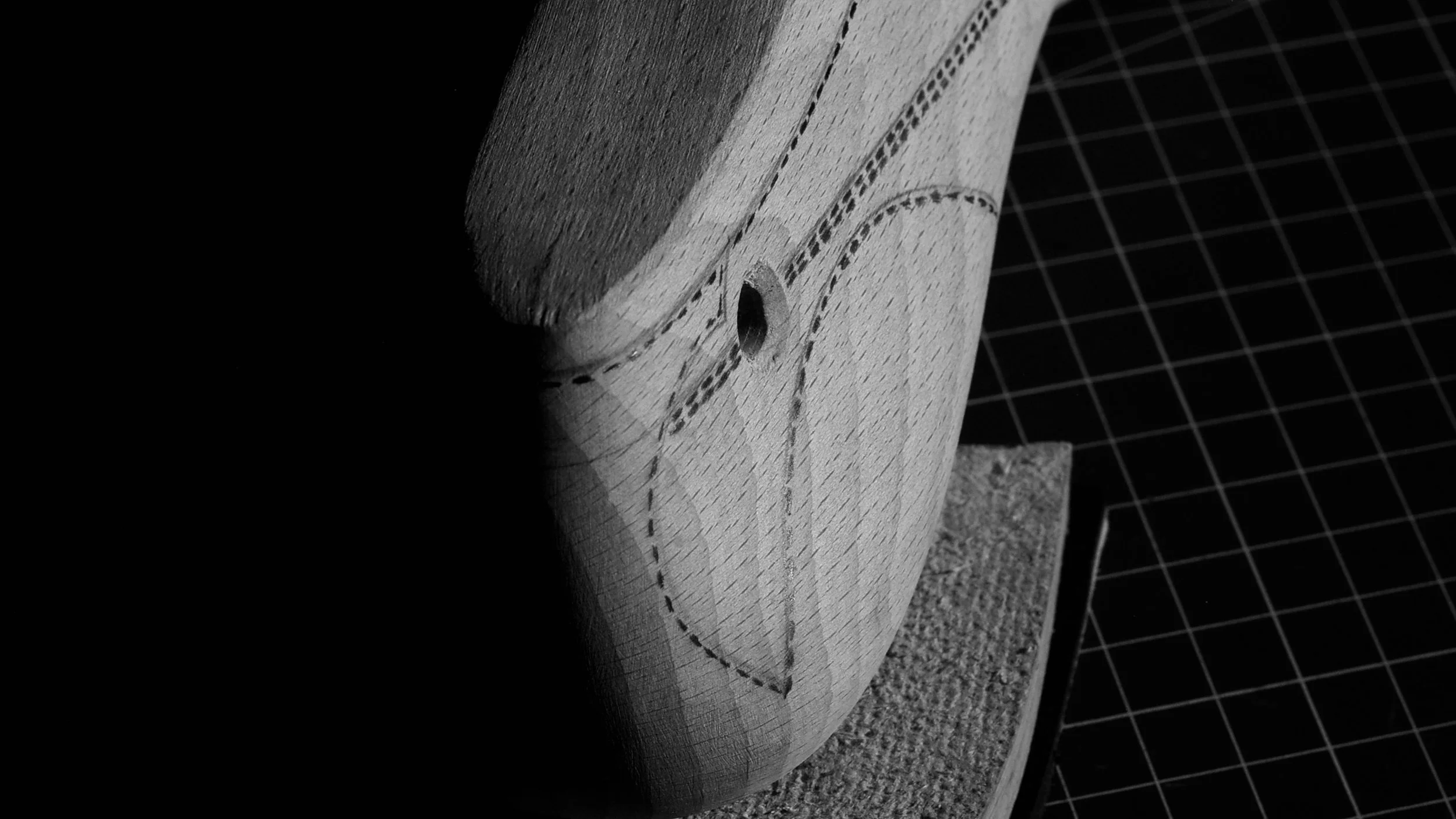

Working on this prototype went quite quickly. The lines are the result of a single design session. It was a successful session. The idea was to capture the design as simply as possible and then try to redesign it if I felt the need after spending some time with it. It's always safe to let this soak in like a seasoning into your mind.

This project has been on my mind long enough to have undergone some changes. I've tried to produce a different upper, even use a completely new last. But I've made my final decisions. You can't keep thinking about it forever...

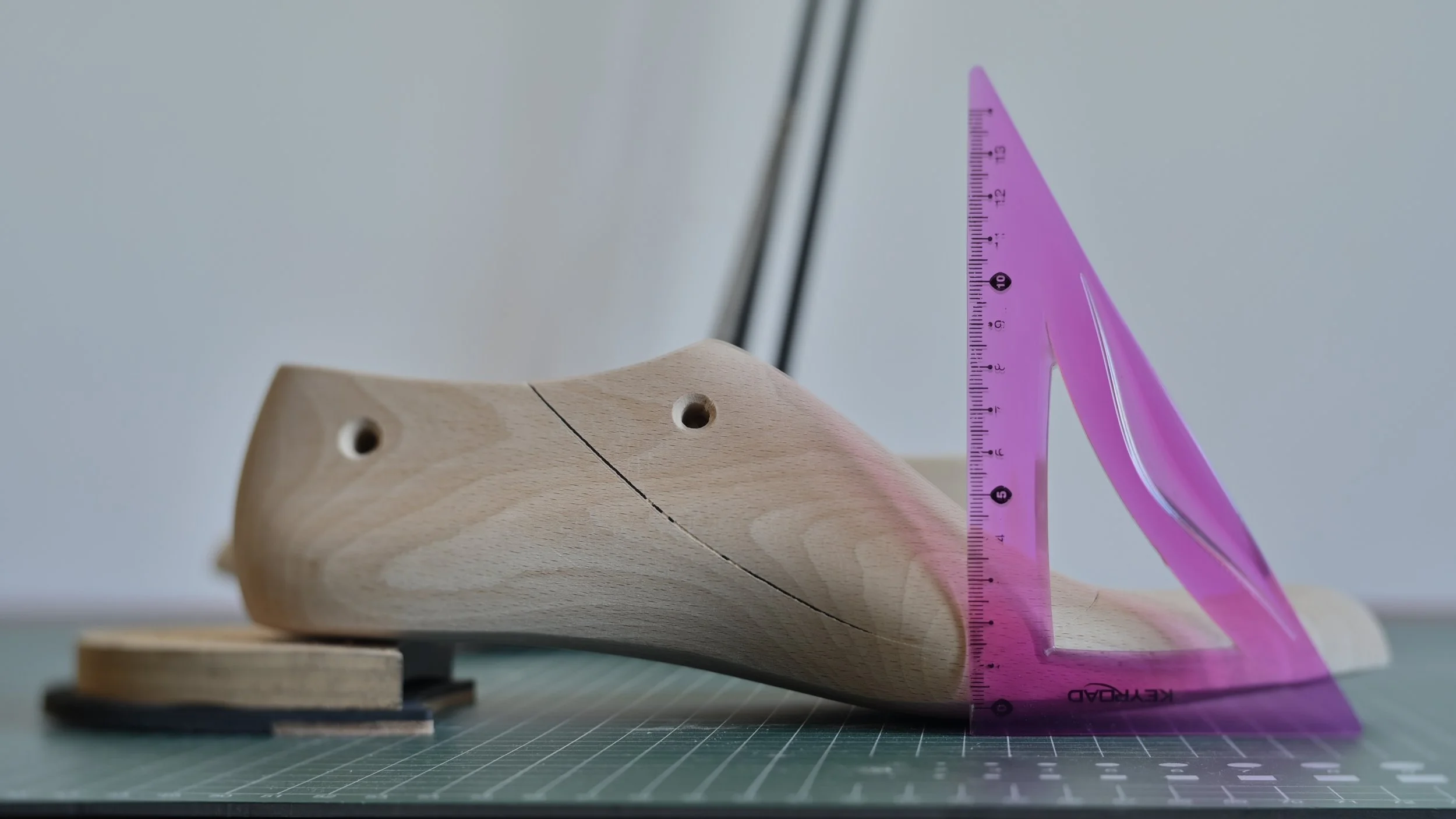

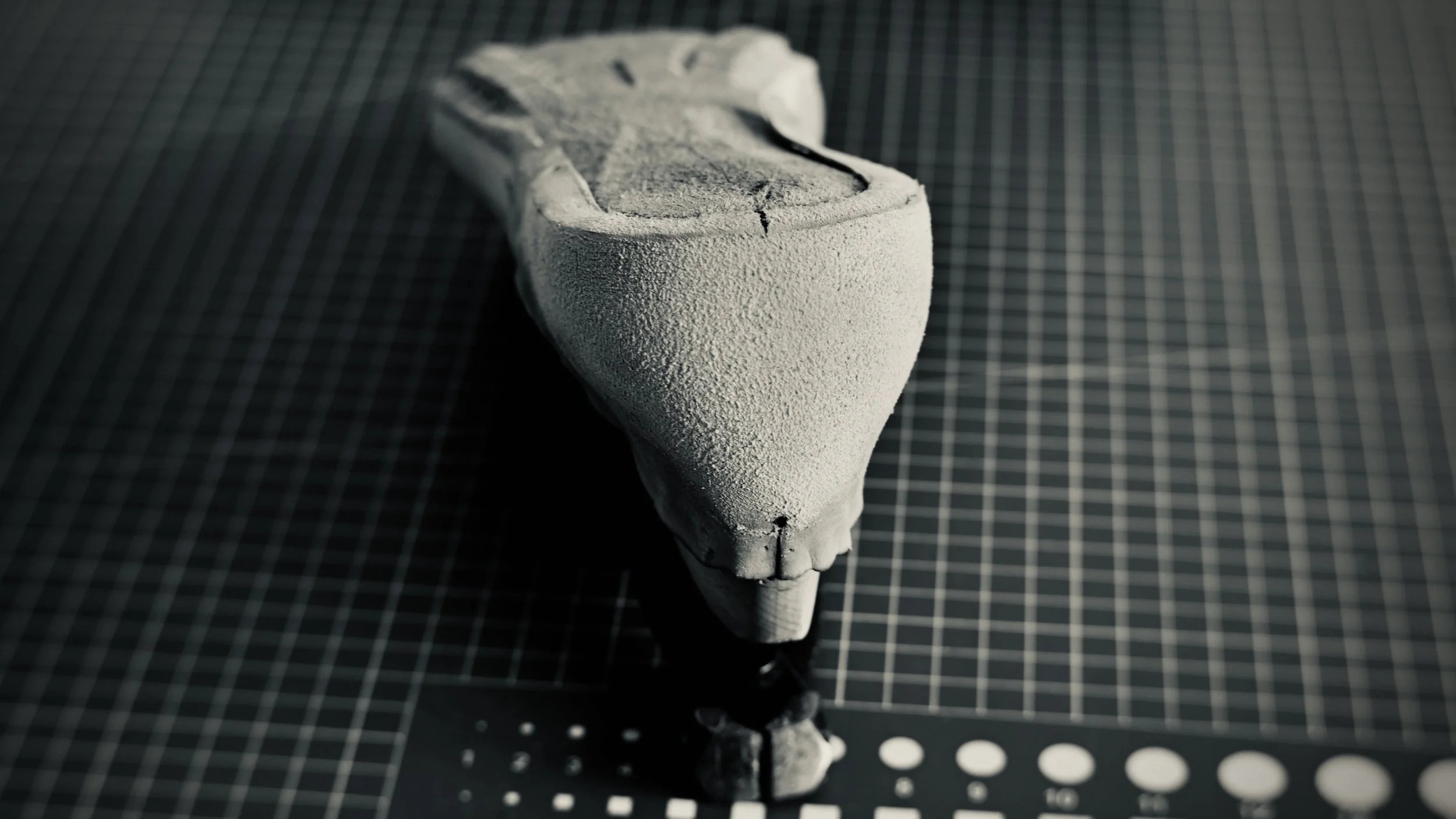

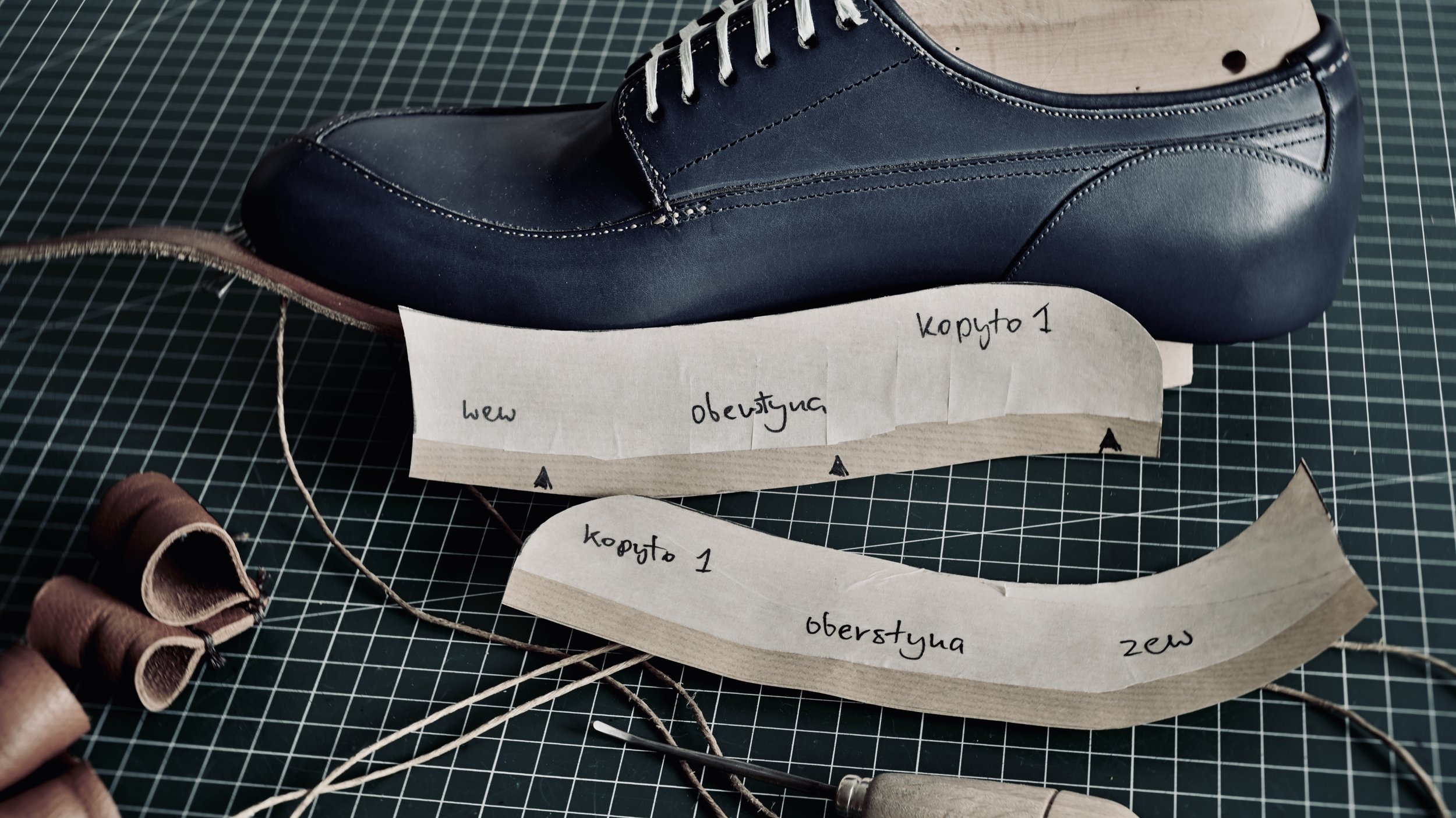

The prototype

Perhaps this derby shoe design will serve us well as a prelude to my first tutorial session. The photo shows my first prototype for this commission. I think it will be interesting to see how the lines and ideas evolve from this stage to the final pair of shoes. In any case, that's the fun of creating fully functional builds.