Considerations

My prototypes have the privilege of covering shoemakers' lasts with an upper that fits like a well-made glove on a delicate hand. Trial and error are just memories.

Now it's like the view from the backseat on the road that was left behind.

My working patterns eagerly await their mastery.

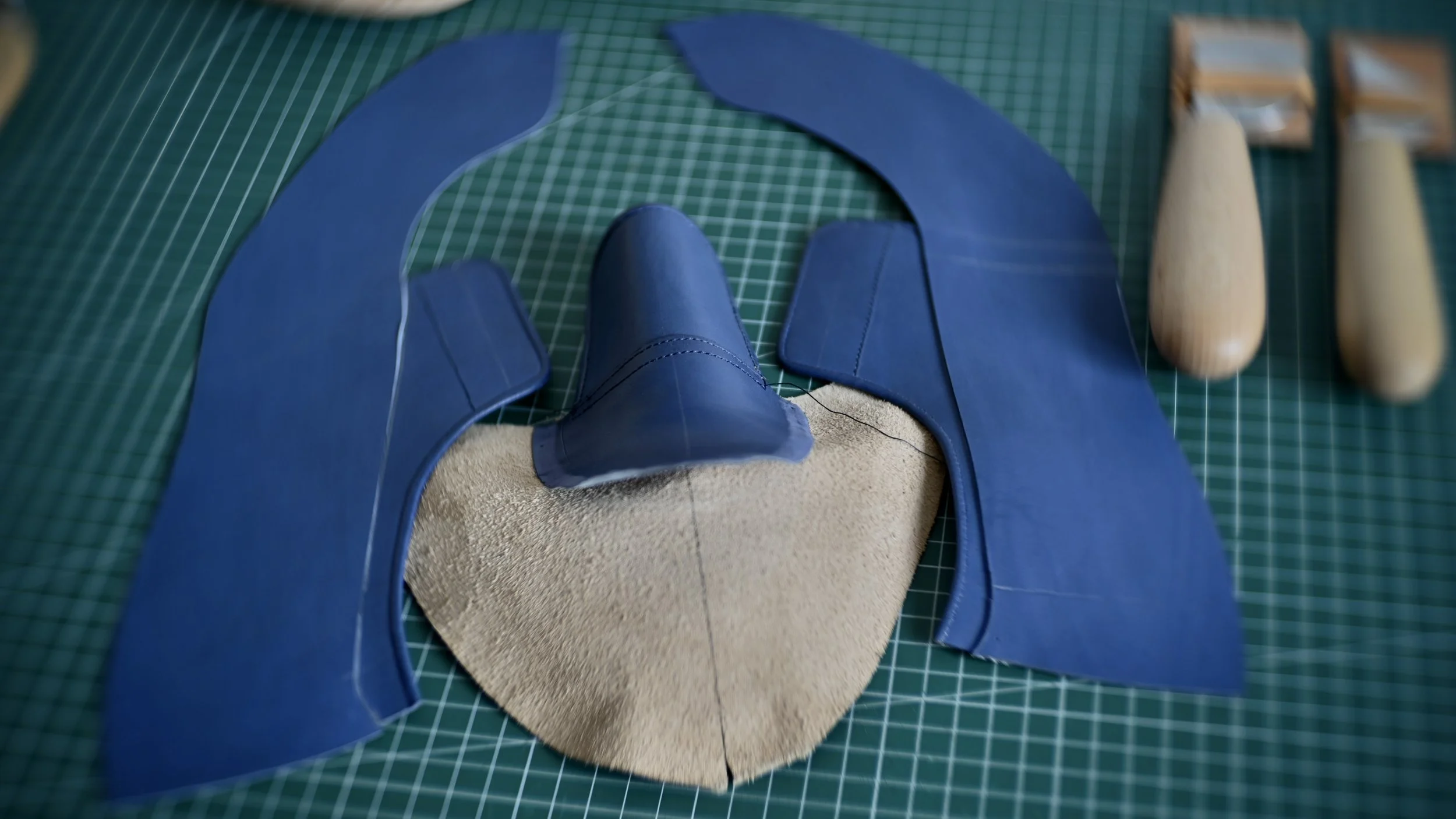

Only one element lacks such a template. The apron is blocked directly on the last, cut out, and sewn in its fully formed form. Combined with the thick lining leather that covers the forefoot, the process of creating the upper becomes a puzzle game.

The insole, my first experiment of this kind, provides excellent arch support and reaches back to hold the heel like a warm, friendly hand.

Some fifteen millimeters of insole leather, trimmed and folded over the shoe last. It's more like an orthopedic job.

But that's not the point. The reason lies in the heel design, which occurred to me a long time ago.

Nothing gives me more confidence than sewing the pieces together.

So I'm gonna stitch the heel in an original way.

My master patterns will be great. The heel counter will be added after initial lasting process is done. There are many details to consider: lining thickness, heel counter with heel stiffener added, correctly determining the heel centerline, measuring the perfect fit around the heel to match the heel counter with the heel breast line in the final assembly…

That's how I work. Things look the way they do because I want them to. I have complete control. Lines are everything in shoemaking.